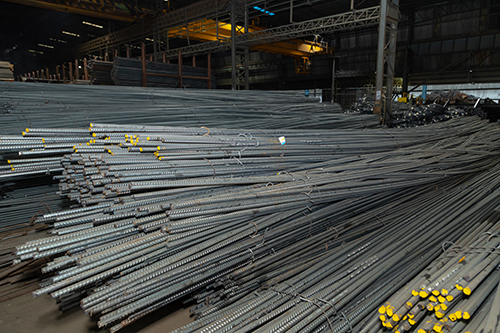

Jagshakti TMT Fe 500

Jagshakti TMT Fe 500

Jagshakti TMT Bars

Jagshakti TMT Bars

Jagshakti TMT Fe 500 is produced from fully killed steel (Prime Steel) Billets, low in carbon, higher yield strength, higher UTS (Ultimate Tensile Strength) and higher percentage elongation when compared to other TMT bars. Its easy bend ability, weld ability & excellent ductility can resist loss of strength at higher temperature. Our TMT can be butt welded or lap welded and accounts for 15% reduction in steel consumption when compared to Cold Twisted Bars.

Features of Jagshakti TMT

- Higher yield strength, Ultimate tensile strength and higher percentage elongation when compared to other TMT bars.

- Easy bend ability, weld ability and excellent ductility ensure economy and safety of use.

- Inbuilt ability to resist loss of strength at higher temperature.

- Require less energy for bending and rebinding along with superior reverse bending properties.

- Can be butt welded or lap welded.

- Use of Jagshakti TMT grade results in saving more tha 15% in steel consumption when compared to cold twisted bars.

- Higher corrosion resistance and seismic resistance compared to other TMT bars.

- Ideally suited for any type of concrete structure.

Produced from fully killed steel (Prime Steel Billets)

| Size (mm) | Standard Weight (Kg/m) | Mini Weight (Kg/m) | Max. Weight (Kg/m) | Tolerance | Size (mm) | Standard Weight (Kg/m) | Mini Weight (Kg/m) | Max. Weight (Kg/m) Batch | Tolerance | ||

| Batch | Individual | Batch | Individual | ||||||||

| 8 | 0.395 | 0.367 | 0.423 | ±7% | -8% | 22 | 2.980 | 2.891 | 3.069 | ± 3% | -4% |

| 10 | 0.617 | 0.574 | 0.660 | ±7% | -8% | 25 | 3.850 | 3.735 | 3.966 | ± 3% | -4% |

| 12 | 0.888 | 0.844 | 0.932 | ±5% | -6% | 28 | 4.830 | 4.685 | 4.975 | ± 3% | -4% |

| 16 | 1.580 | 1.501 | 1.659 | ±5% | -6% | 32 | 6.310 | 6.121 | 6.499 | ± 3% | -4% |

| 18 | 2.000 | 1.940 | 2.060 | ±3% | -4% | 36 | 7.990 | 7.750 | 8.230 | ± 3% | -4% |

| 20 | 2.470 | 2.396 | 2.544 | ±3% | -4% | 40 | 9.860 | 9.564 | 10.156 | ± 3% | -4% |

| Length | Standard |

| Uniform 12 meters, can also be supplied In 9/12 meters on mutual agreement |

NS: 191- 2046 |

Comparison of Fe 500 with International Standards

| Standard | Grade | UTS N/MM2 |

YS N/MM2 |

% Elongation |

| ASTMA 615 | 75 | 690 | 520 | 6.7 |

| JISG 3112 | SD 490 | 620 | 490-625 | 12-13 |

| BS 4449 | 500 | 525-675 | 500 | 12 |

| DIN 488 | BST- 500 | 550 | - | 8 |

| New Zerland | 500 N | 650 | - | 5 |

| Australia | 500 N | - | 500 | - |

| NS 191 | Fe 500 | 545 | 500 | 12 |

| NS 191 | Fe 500 D | 565 | 500 | 16 |

| JAGSHAKTI TMT (Typical) | Fe 500 | 648 | 550 | 22 |

Advantages of JAGSHAKTI TMT (QST) Rebars

Combination of high strength and high ductility

JAGSHAKTI TMT bars have rare combination of high strength with excellence of ductility. The tensile to yield strength ratio is always greater than 1.12. In normal bars, the increase in the yield strength of the bars is accompanied by the loss of percent elongation. But in the case of JAGSHAKTI TMTbars this loss is negligible and the percent elongation values are much higher than normally specified in various International Standards.

This excellent feature of Jagshakti TMT make it the perfect choice in earthquake prone areas as higher ductility with high strength ensures that any structure made with Jagshakti TMT will lstland strong in the most rigorous and high seismic zone areas."

Resistance to ageing

The test carried out on the Jagshakti TMT bars, indicate that no significant change of strength and function of time occurs which could affect the usefulness of these bars.

Superior Corrosion resistance

The absence of Eutectoid Carbides and pearlite colonies in presence of martenstic layer at the outside surface and formation of adherent scale film due to water quenching during rolling area the reasons for better corrosion resistance properties of these reinforcement bars.

Excellent bendability and workability

The Tough outer skin and the ductile core of the JAGSHAKTI TMT bars result in excellent bendability. This coupled with a high resistance to low temperature brittle fracture, allows these bars to bent , without fear of failure around small diameter mandrels.

In the reverse bend test, these bars also show good result. In the construction site, situation arises where bars bent are left for a good period in the bent condition and then reverse bent. During period between the first bend and the reverse bend the bars may strain age. The loss of ductility due to strain ageing and due to strain imposed from the first bend may cause failure ductile. Test results have shown that JAGSHAKTI TMT bars have withstood successfully the bending , straightening and rebinding tests after ageing. The bend tests carried out at our lab have shown that these bars could be bent even around the smallest dia. mandrel without causing any cracking.

Can be butt welded or lap welded

The low carbon content and low carbon equivalent of JAGSHAKTI TMT reinforcement bars ensure excellent weld ability even while using any of the welding processes such as arc welding, flash butt welding, gas shielded semi automatic welding, gas pressure welding and resistance welding etc.

Welding of these bars does not require pre- heating or post heating. JAGSHAKTI TMT bars indicate good welding properties in case of butt welds, cross welds and lap welds. Tensile tests carried out on these reinforcing bars after butt welds jointed. Normal electrodes with matching strength can be used for welding.

In the welding of steels, the tendency to produce hard and brittle heat affected zones is maximum when the cooling rates of the weld and the carbon content are high. In addition, In those welding process where molten metal filler is used, such as in manual metal arc welding, hydrogen pick up may occur lending to hydrogen induced cracking in the heat affected zone. In case of welding reinforcement bars hard brittle of low duce to fast cooling rates. JAGSJAKTI TMT bars have got very low susceptibility to both heat affected zone brittleness and hydrogen induced cracking due to their low carbon content. These bars when welded show no loss of strength at the load carrying joints.