Torkari

Torkari is a high strength and high bond reinforcing steel and is the spine in concrete members conforming to Fe 500 OR 550 GRADE (TOR-50/55) of IS 1786-2008). Torkari also conforms to international standards like: din – 488 (Germany), BS – 4483, 4449(UK), ASTM – A 497 (AMERICAN).

Torkari is a high strength and high bond reinforcing steel and is the spine in concrete members conforming to Fe 500 OR 550 GRADE (TOR-50/55) of IS 1786-2008). Torkari also conforms to international standards like: din – 488 (Germany), BS – 4483, 4449(UK), ASTM – A 497 (AMERICAN).

TOR-KARI steel reinforcement bars (TOR 50/55 Grade) are made by a process of cold rolling from mild steel coils and consequently come out in small diameters from 4.5 mm to 9 mm. This range of sizes will not only cause structurally superior components in addition to savings in steel consumption, in comparison to the 40 Grade bars which come in a minimum dia of 8 mm. Conventional high strength deformed bars of Fe 415 grade of dia 8 mm and 10 mm can be conveniently replaced by High Strength TOR-KARI reinforcement bars (TOR 50/55 Grade) of dia 7mm and 9mm. TOR-KARI of dia 5mm can also economically replace mild steel bars of dia 6/6.8 mm often used as secondary reinforcement.

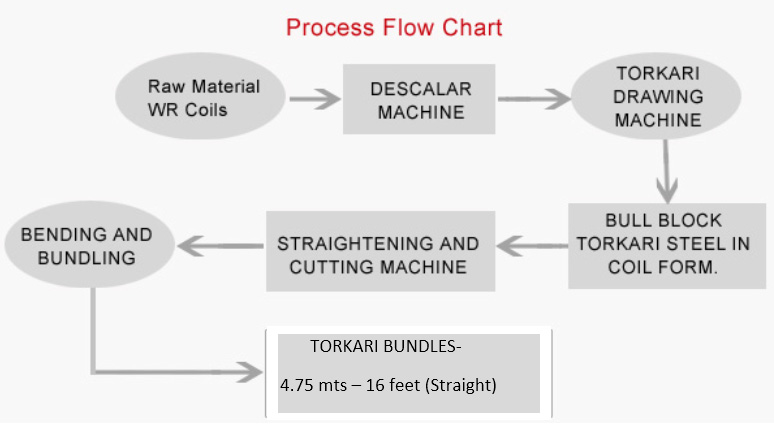

Manufacturing Process

Manufacture of Torkari steel by Wire drawing Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die(s). Drawing is usually performed at room temperature, thus classified as a cold working process.

The Raw Material

LOW CARBON STEEL WIRE ROD COILS – conforming to IS: 226, 2062, 7887, SWR 14, SAE 1010-1015 (ASTM Standards).

These WRC are imported from Indian suppliers like RINL (VSP), JSW Steels, SAIL and Tata. They are also imported from China, Turkey, and Indonesia. MADE FROM 100% GENUINE BILLET.

Advantages of using TORKARI

- The Quality Advantage

- The Cost Advantage

- The Size Advantage

The Quality Advantage

Superior Strength

fy = 550 N/sq.mm.

Ultimate = 585 N/sq.mm

Over 30% when compared to Tor 40 or Fe-415 where fy=415 N/sq.mm viz. 550/415 = 1.33 times.

The Quality Advantage

High Bond Properties

Torkari is Tri-Ribbed viz. Rib on three sides.

TMT and TOR-40 have ribs only on two sides.

Even 5mm TORKARI has ribs whereas 6mm MS is plain.

Bond strength is over 100%.

LESSER CRACK WIDTH DUE TO HIGH BOND.

Rolling Tolerance

Since the strength is more, it results in less area of reinforcement, thus reducing congestion of reinforcement.

As per IS code the acceptable rolling tolerance is 7%. In TORKARI due to its superior technology the rolling tolerance is restricted to 4%

Easily Weldable

100% Weldability

Being made from Low carbon mild steel with carbon less than 0.20%, it can be welded by metal arc welding process with normal electrodes.

CTD, TMT (local rerollers) bars and 6mm MS are usually rerolled from scrap / ingots where the carbon content is not controlled. In fact the main reason for breakage during bending is due to rolling from scrap and high carbon content.

Other Quality Advantages

- Better fatigue strength.

- Advanced German Technology.

- Built in high creep resistance through adequate cold working.

- TRFI guidance and certification.

- Well-equipped QC lab at factory. Client’s witness of testing can be arranged before dispatch. Can be used with any grade of Concrete.

Satisfactory Bendability

TORKARI can be bent to form any type of hooks – U type or L type and also to form stirrups and ties by adopting suitable bend radius of over 25mm as per IS: 2052 – 1963.

Mandrel (Pin dia) for TORKARI for Bending.

(5 times the dia)

- 5mm TORKARI = 25 mm

- 7mm TORKARI = 35 mm

- 9mm TORKARI = 45 mm

(At least ensure the pin dia is 25mm at Site.)

The Size Advantage

- Smaller diameters from 5mm onwards.

- Available in 5mm, 7mm.

- 5mm TORKARI can be used in place of 6mm MS.

- 7mm TORKARI can be used in place of 8mm Tor-40.

Specifications – Fe-550 Grade (As Per Is 1786-2008)

Data of Available DIA:

| Nominal Dia mm |

Nominal Weight Kg/m |

Permitted range of weight kg/m |

Range of length Mts/MT |

Ast Sq.mm |

| 5.0 | 0.154 | 0.142 to 0.166 | 6024 to 7042 | 19.63 |

| 7.0 | 0.302 | 0.278 to 0.326 | 3065 to 3598 | 38.48 |

Mechanical Properties:

| Parameters | IS Requirements | Torkari specs |

| 0.2% Proof Stress (P.S) | 550 N/sq.mm (Min.) | Passes |

| Ultimate Tensile Strength | 585 N/sq.mm (Min.) Or 1.06 X Act P.S whichever is higher | Passes |

| Elongation | 10% Min. | Above 13% |

| Bond Strength ( Extra Over Plain Round) | 60% Min. over Mild Steel | Above 100% |

| Weight Tolerance | + or – 8% | 4% |

Chemical Properties:

| Parameters | IS Requirements | Torkari specs |

| Carbon | 0.30% Max | 0.20% Max |

| Sulphur | 0.055% Max. | 0.045% Max |

| Phosphorus | 0.050% Max. | 0.045% Max> |

| Sul+Phos | 0.10% Max. | 0.090% Max. |

Specifications – Fe-500 Grade ( As Per Is 1786-2008 )

| Nominal Dia mm |

Nominal Weight Kg/m |

Permitted range of weight kg/m | Range of length Mts/MT |

Ast Sq.mm |

| 5.0 | 0.154 | 0.142 to 0.166 | 6024 to 7042 | 19.63 |

| 7.0 | 0.302 | 0.278 to 0.326 | 3065 to 3598 | 38.48 |

Mechanical Properties:

| Parameters | IS Requirements | Torkari specs |

| 0.2% Proof Stress (P.S) | 500 N/sq.mm (Min.) | Passes |

| Ultimate Tensile Strength | 545 N/sq.mm (Min.) Or 1.08 X Act P.S whichever is higher | Passes |

| Elongation | 12% Min. | Above 14.5% |

| Bond Strength ( Extra Over Plain Round) | 60% Min. over Mild Steel | Above 100% |

| Weight Tolerance | + or – 8% | 4% |

Chemical Properties:

| Parameters | IS Requirements | Torkari specs |

| Carbon | 0.30% Max | 0.20% Max |

| Sulphur | 0.055% Max. | 0.045% Max |

| Phosphorus | 0.050% Max. | 0.045% Max |

| Sul+Phos | 0.105% Max. | 0.090% Max. |