Another variety of MS Black Pipe is Square Hollow Section (SHS) pipes and Rectangular Hollow Section (RHS) pipes. By virtue of their shapes hollow sections have high radius of gyration and other properties resulting in savings in material, transportation and fabrication cost. Less Surface Area compared to equivalent conventional sections also results in savings in Paint and Labour Cost.

Another variety of MS Black Pipe is Square Hollow Section (SHS) pipes and Rectangular Hollow Section (RHS) pipes. By virtue of their shapes hollow sections have high radius of gyration and other properties resulting in savings in material, transportation and fabrication cost. Less Surface Area compared to equivalent conventional sections also results in savings in Paint and Labour Cost.

Also less exposed Surface Area combined with superior quality raw material results in less corrosion. Moreover smooth uniform profiles of sections minimizes dust and moisture accumulation. Nowadays, these pipe are being used abundantly in steel furniture and predominantly in huge structural like Airports, Malls etc. SHS and RHS have also become very popular in many forms of construction and other structural & mechanical applications. This has been greatly assisted by the section's inherent flat surfaces making it more economical for joining and other fabrication processes. ln this instance, and unlike Round Pipes, the sections only need to be straight-cut (when joining to other at surfaces) instead of profile cut (e.g. when preparing a Circular end or when joining to curved surfaces). Minimal edge preparation is required for joining and welding RHS. SHS and RHS can be used for architectural aesthetics, possessing clean lines, it is functional and interacts less with external environmental effects.

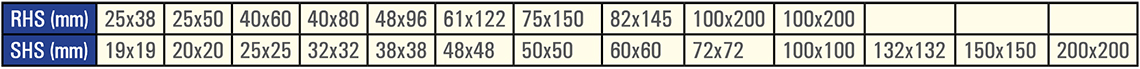

The Product list is as follows:

The above pipes are manufactured in different thicknesses ranging from 0.40 mm to 6.00 mm as per the customers requirement.

SHS Pipes

SHS Pipes

Tube Mill